The Hydraulic Plate Compactor is an excavator attachment widely used in various foundation projects such as construction projects, road projects, and bridge projects. It is especially effective in foundation treatment of soft soil or fill sites. It can improve soil properties quickly and efficiently, increase the bearing capacity of the foundation, and shorten the project cycle.

HMB Hydraulic Plate Compactor Has Four Advantages:

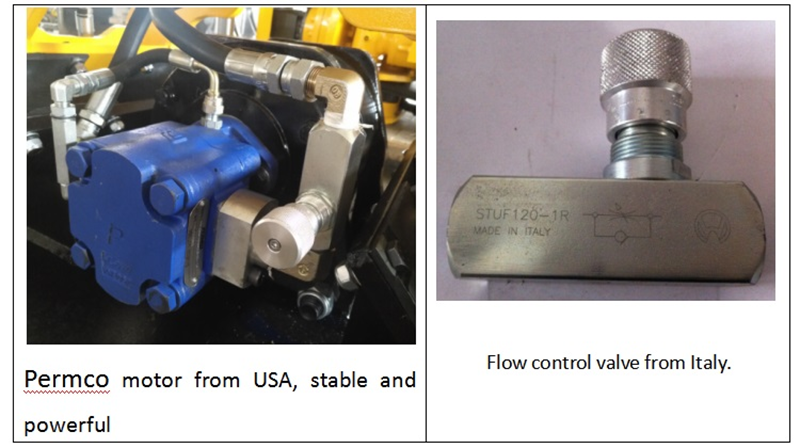

1. Core Accessories & Strike Efficiency

The motor and bearing we use are originally imported, with a speed of up to 6000 RPM, while others in the market are roughly 2000-3000 RPM. High-quality accessories bring high work efficiency, the striking frequency of Jiangtu Hydraulic Plate Compactor can reach up to 1000 per minute, the striking speed is fast and the strength is strong so that its similar products can not be matched.

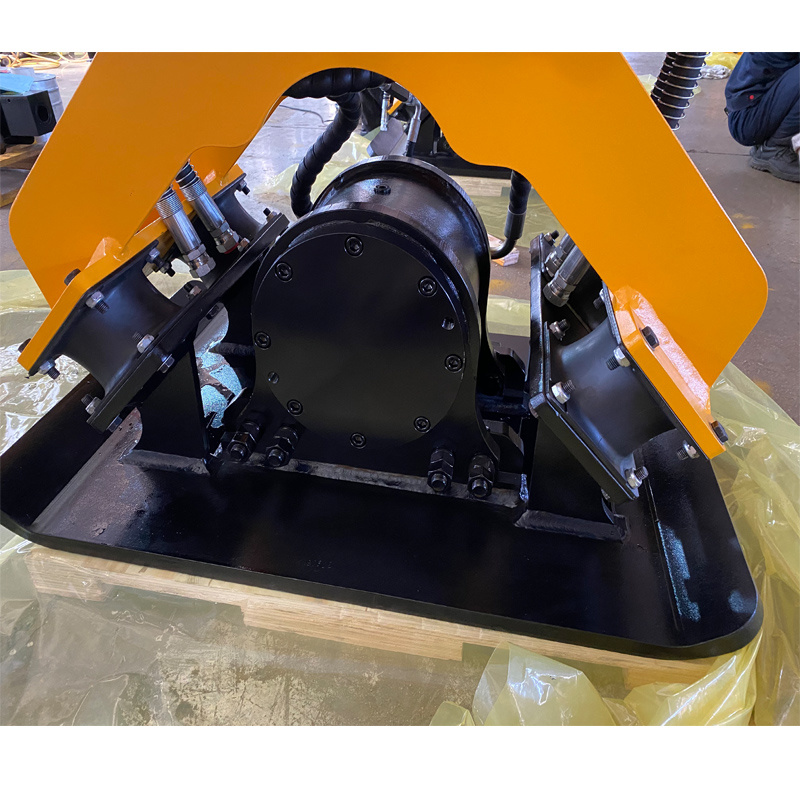

2. Wear-Resistant Plate

One of the important components of the Hydraulic Plate Compactor, HMB uses imported wear-resistant plates. The material and thickness are above average and will not deform after long-term use. Poor quality wear-resistant plates will have “symptoms”of different thicknesses after a short period of use, but HMB’s Hydraulic Plate Compactor will not have such”symptoms”.

3. Valve Core

Hydraulic Plate Compactor is equipped with a throttle valve and a safety valve, the function of the throttle valve is to control this valve to limit the output frequency. The safety valve is used to protect the product during use.

Safety Instructions

In order to ensure the use efficiency of the hydraulic plate compactor, not only maintenance work should be done well, but there are still some problems that need to be paid attention to during the use process. The following HMB will introduce the precautions for the use of the hydraulic plate compactor.

1. When turning on the hydraulic plate compactor, please place the device on the object being rammed, and make sure to use a small pressure within the first 10-20 seconds. Different pressures can be selected according to the different ramming objects.

2. If the hydraulic hydraulic plate compactor needs to be kept properly when it is out of use for a long time, the oil inlet and outlet should be sealed, and it should be stored in the environment of high temperature and below -20 degrees.

3. The hydraulic breaker and fiber rod should be perpendicular to the working surface during use, and the principle of not generating radial force is the principle.

4. When the rammed object has broken or started to crack, the impact of the hydraulic plate compactor should be stopped immediately to avoid harmful “empty hitting”.

5. When the hydraulic hydraulic plate compactor is working, it is necessary to press the rammer plate on the rock and maintain a certain pressure before starting the breaker. It is not allowed to start in the suspended state.

6. After completing daily work, do not put overloaded objects in the vibration frame. When storing, twist the compacting plate to the side or bottom of the hydraulic plate compactor. When storing, twist the compacting plate to the side or bottom of the equipment.

The excavator compactor has outstanding features such as good compaction effect, high productivity, small volume and weight, lightness and flexibility, etc. It is well received by users and has been rapidly popularized and used.

IF you have any need,please contact HMB,

whatsapp:+8613255531097

Email:hmbattachment@gmail.com

Post time: Jan-08-2024