Hydraulic shears have become an essential tool in the demolition industry, revolutionizing the way buildings and structures are demolished. When combined with the power and flexibility of an excavator, the results are truly impressive. HMB eagel shear is one of the most reputable brands on the market and has been at the forefront of producing top-quality hydraulic shears that deliver superior performance and efficiency, making them the first choice for contractors and demolition experts.

Hydraulic shears are specially used with excavators, which are flexible in operation, effectively utilize the hydraulic power of the excavator, give full play to the mobility of the excavator, greatly save costs, improve work efficiency, and move the demolition project to a new stage. Your excavator realizes multiple functions in one machine and improves investment efficiency. Especially suitable for house demolition, crushing, metal material cutting and other projects.

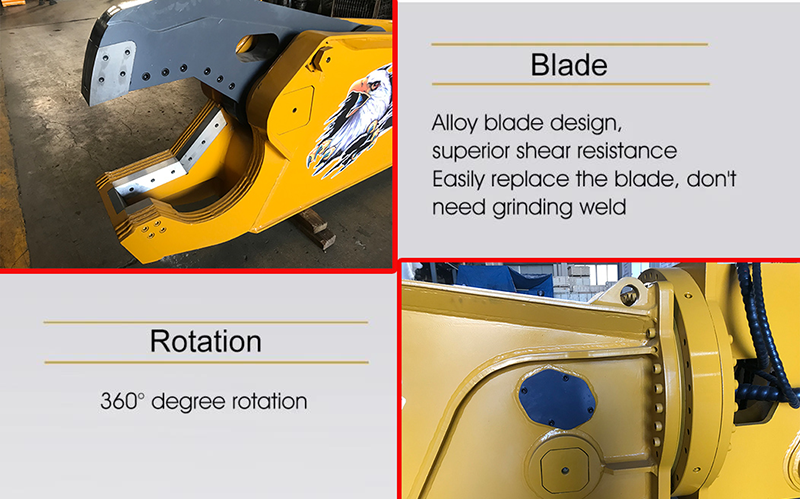

Hydraulic shears are composed of a shelf, a connecting body, ascissors body, a scissors blade, a motor, a cylinder and other accessories, so that the high-altitude hydraulic shears can realize rapid opening and closing,360-degree rotation and other actions, and have a wide spreading range and powerful Its crushing strength, superior performance in dismantling and recycling, simple structure and easy maintenance, and replaceable cutting blades to extend the service life

Hydraulic shears have the characteristics of reasonable structure, not easy to damage, simple maintenance, high working efficiency, no damage to the excavator, and low working noise. During the demolition operation, only a few girders need to be cut to make the entire building collapse, thereby greatly improving the work efficiency

Product Advantage

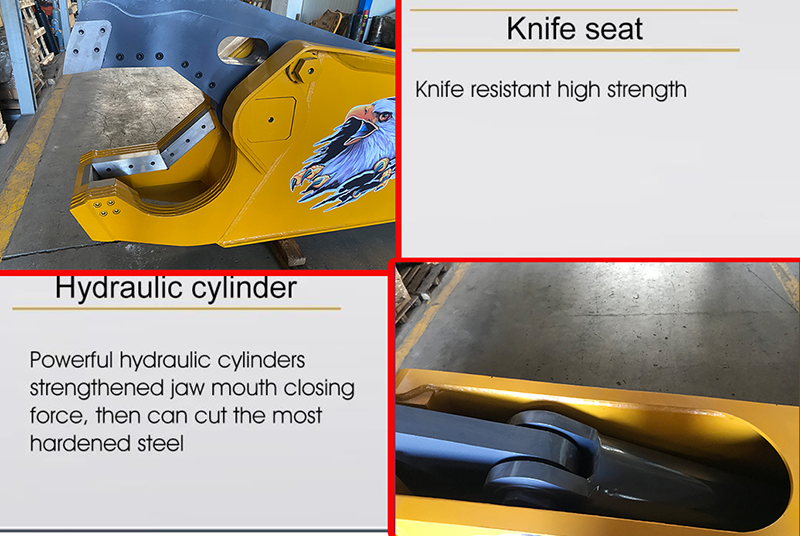

* Jaw size and special blade desigh to increase productivity. All hydraulic shears series can quickand convenient to replace the blade, can reduce machine downtime and optimize productivity.

* Powerful hydraulic cylinders strengthened jaw mouth closing force, then can cut the most hardened steel.

Operating principle:

Hydraulic pulverizer is composed with body, hydraulic cylinder, movable jaw and fixed jaw. The external hydraulic system offer hydraulic pressure for the hydraulic cylinder to make the movable jaw and fixed jaw open and close to achieve the effect of crushing objects.

Engineering application scope:

·Apartment building, Workshop beams, Houses and other buildings demolition

·Steel recycling

·Concrete crushing

Performance Parameter

| Model | Weight | Overall length | Max

Opening |

Oil pressure | Suitable excavator weight | Dimensions |

| HMB250R | 2300kg | 2800mm | 450mm | 32Mpa | 20-30T | 2800*700*1000mm |

| HMB350R | 3150kg | 3370mm | 620mm | 32Mpa | 35-45T | 3370*800*1200mm |

| HMB S450R | 4900kg | 3900mm | 800mm | 32Mpa | 400-50T | 3900*880*1350mm |

Safety precautions

1.Operators shall be professionally trained to understand the structure, principle, operation and maintenance methods of the upper air hydraulic shear operated. And hold the operation certificate, can operate.

2. Failure of high altitude hydraulic cutting and ordering cannot be handled without authorization, and after-sales personnel should be contacted in time.

3. The test, installation, disassembly and hauling of high altitude hydraulic shear should strictly follow the relevant regulations.

4. In the case of thunder, rain, snow, fog and wind above six levels, the operation should be stopped. When the wind speed exceeds seven or there is a strong

typhoon warning, the hydraulic shear should be placed against the wind, and it should be put down when necessary.

5. Before operation, the operation should be carried out in empty first, and the operation can be carried out after the status of all parts is determined to be normal.

6. In the working process of high altitude hydraulic shear, the blade edge must be kept sharp, dull or crack phenomenon, should be replaced in time.

7. It is forbidden to pick up the waste on the ground when high altitude hydraulic shear works, in order to avoid being hit by the falling workpiece. The waste produced after the operation is angular, the operator should be cleared in time to prevent being stabbed and cut.

Storage of Hydraulic Shear

At the end of the work of the hydraulic shear,the hydraulic oil and some parts still have hight oil and some parts still have hightemperature waste heat. Be carefull!

1.Before storge,added enough butter and store in a dry place.Butter should also be added to the rusty area.Changes in humidity and temperature can cause rust and corrosion.

2.If storing with a hose,seal the hose opening with a plug.If the hose is not connected,seal the opening with a cap to prevent hydraulic oil from leaking or other substances from entering.

3.Put the hydraulic shear on the wooden board to ensure that the wooden board is strong enough to bear the equipment.When removing hydraulic hoses,check for oil

leakage and dispose of them in accordance with waste disposal regylations.

4. When storing equipment for a long time:

(1) Clean and dry all parts and store in a vebtilated environment.

(2) Clean up at leaset once a month and Lubricate functional parts.

(3) Add grease to the cylinder rod and other parts are easy to rust.

If you need any excavator attchment,please contact HMB excavator attachment whatsapp:+8613255531097,HMB is a one-stop service experters

Post time: Feb-20-2024