Excavator breaker chisels are powerful tools that are used in various industries for demolition and construction purposes. They consist of several key components that work together to deliver high-performance results.

One of the main components is the steel body, which provides strength and durability to withstand heavy-duty operations. The body is designed to handle extreme forces and vibrations without compromising its integrity.

Applications Of Excavator Breaker Chisels

Excavator breaker chisels, also known as hydraulic breakers or rock breakers, have a wide range of applications in various industries. These powerful tools are designed to break through hard materials such as concrete, asphalt, and rocks with ease. Let’s take a look at some of the common applications where excavator breaker chisels prove invaluable.

• Construction: In the construction industry, these chisels are used for demolition work, whether it’s breaking down old structures or removing concrete foundations. They can also be utilized for excavation tasks like digging trenches and breaking up compacted soil.

• Mining: Excavator breaker chisels play a crucial role in mining operations by helping to extract minerals from underground deposits. They can effectively break through tough rock formations and facilitate easy extraction.

• Road maintenance: When it comes to road repairs and maintenance, excavator breaker chisels are essential tools. They make quick work of removing damaged pavement sections, cutting through asphalt layers, and breaking up stubborn concrete patches.

• Quarrying: Quarries rely on excavators equipped with breaker chisels to extract stones from large blocks or boulders safely and efficiently. The precise control provided by these tools ensures minimal waste during stone extraction processes.

• Landscaping: Whether it’s creating ponds or shaping terrain features in landscaping projects, excavator breaker chisels offer precision and power required for earthmoving tasks without damaging surrounding areas.

• Infrastructure development: From demolishing old bridges and tunnels to breaking down reinforced structures during new infrastructure development projects like railways or highways the excavator breaker chisel plays an important role here too!

The versatile nature of excavator breaker chisel makes them indispensable across multiple industries. They provide efficiency, safety, and cost-effectiveness in various applications ranging from construction and mining to quarrying and road maintenance.

Selection And Maintenance Of Excavator Breaker Chisels

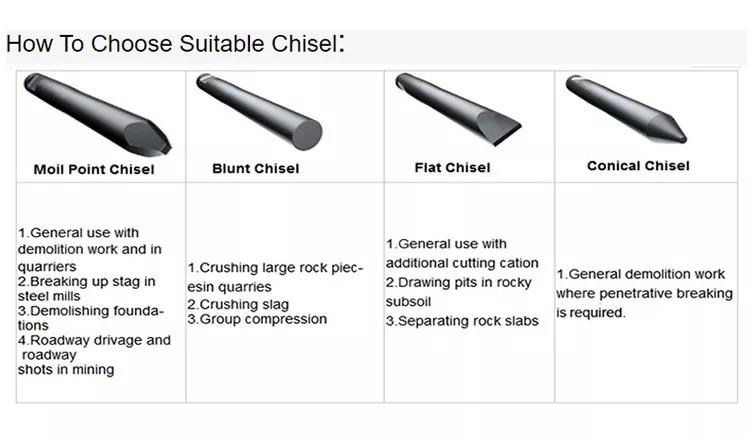

Selection and maintenance are crucial aspects when it comes to excavator breaker chisels. Choosing the right chisel for your excavator is essential to ensure optimal performance and productivity. Consider factors such as the type of material you will be breaking, the size and weight of your excavator, and the specific requirements of your job site.

When selecting a breaker chisel, make sure it is compatible with your excavator’s hydraulic system. The size, shape, and mounting configuration should match perfectly to avoid any compatibility issues. Additionally, consider the durability and strength of the chisel material to withstand tough working conditions.

Regular maintenance is vital to prolonging the lifespan of your breaker chisels. Inspect them before each use for signs of wear or damage. Check for cracks or fractures in the tool steel as these can compromise its effectiveness and safety during operation.

Proper lubrication is also essential for smooth functioning of the chisel. Use recommended grease or oil specified by the manufacturer on a regular basis.

Additionally, keep an eye on hydraulic pressure levels to ensure they remain within the correct range. Excessive pressure can lead to premature wear while insufficient pressure may result in poor performance.

Safety Considerations When Using Excavator Breaker Chisels

When it comes to operating heavy machinery like excavators, safety should always be the top priority. This is especially true when using excavator breaker chisels, as they can be powerful tools that require careful handling. Here are some important safety considerations to keep in mind:

• Proper Training: Before using an excavator breaker chisel, ensure that you have received proper training on its operation and safety guidelines. Familiarize yourself with the equipment’s controls and functionality.

• Protective Gear: Always wear appropriate personal protective equipment (PPE) such as a hard hat, safety glasses, ear protection, gloves, and steel-toed boots when operating an excavator with a breaker chisel attachment.

• Inspect Equipment: Before starting any work, inspect the excavator and breaker chisel for any signs of damage or wear. Check hydraulic lines for leaks and ensure all connections are tight.

• Secure Work Area: Clear the work area of any bystanders or obstacles before beginning operations with the breaker chisel attachment. Ensure that there is enough space for the safe movement of both the machine and surrounding personnel.

• Use Stable Ground: Operate the excavator on stable ground to prevent tipping or sliding accidents while using the breaker chisel attachment.

• Maintain Proper Distance: Keep a safe distance from other workers while operating the excavator with a breaker chisel attached to avoid potential injuries caused by flying debris or accidental contact.

• Regular Maintenance: Follow manufacturer recommendations for regular maintenance checks on both the excavator and breaker tool to ensure optimal performance and reduce risks associated with faulty equipment.

Remember that these are just some general safety considerations when using an excavator breaker chisel; always refer to specific guidelines provided by your employer or equipment manufacturer for comprehensive instructions tailored to your specific situation.

Conclusion

Excavator breaker chisels are essential tools in the construction and demolition industry. With their powerful hydraulic systems and durable chisel heads, they can effectively break through tough materials like concrete and rock. These versatile attachments have revolutionized the excavation process by increasing efficiency and reducing labor-intensive methods.

When selecting an excavator breaker chisel, it is crucial to consider factors such as compatibility with your machine’s specifications, the type of work you will be doing, and the material you need to break. Regular maintenance is also key to ensuring optimal performance and longevity of your equipment.

However, it’s important to always prioritize safety when using excavator breaker chisels. Proper training on operating procedures and adherence to safety guidelines can prevent accidents or injuries on-site.

So whether you’re involved in heavy construction projects or smaller-scale demolition jobs, investing in a reliable excavator breaker chisel can greatly enhance your productivity while minimizing manual labor requirements.

Remember that choosing the right tool for the job is essential for getting the best results. So make sure to do thorough research before purchasing an excavator breaker chisel that suits your specific needs.

Post time: Jul-21-2023