In the world of industrial manufacturing and metalworking, precision and efficiency are paramount. One of the key tools that embodies these qualities is the hydraulic shear. Hydraulic shears are powerful cutting machines that utilize hydraulic pressure to precisely cut through a variety of materials, primarily metals. With their ability to handle a wide range of tasks and produce clean, accurate cuts, hydraulic shears have become indispensable assets in various industries.

The Mechanics Behind Hydraulic Shears

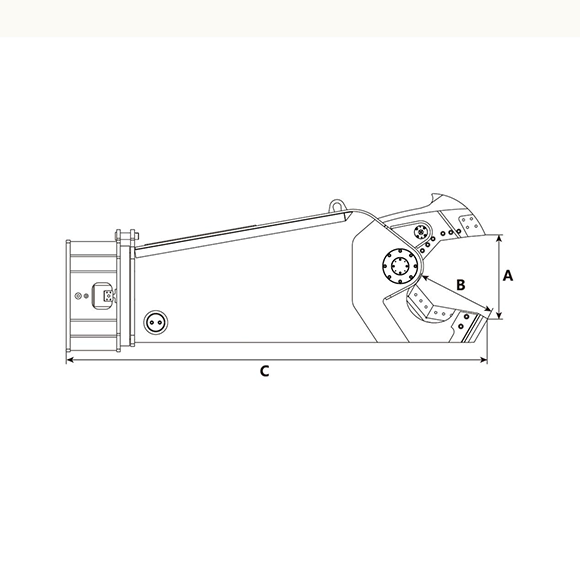

Hydraulic shears operate on the principle of fluid mechanics, utilizing hydraulic pressure to generate the force needed for cutting. The key components of a hydraulic shear include a hydraulic fluid reservoir, a hydraulic pump, control valves, a cutting blade or blades, and a frame to support the entire structure.

The process begins with the hydraulic pump pressurizing the hydraulic fluid, typically oil. This pressurized fluid is then directed through control valves that regulate the flow and pressure. These valves are operated by the machine operator, who can control the cutting process with precision.

The pressurized hydraulic fluid is transmitted to hydraulic cylinders, which in turn generate a powerful force that moves the cutting blade(s) downward onto the material to be cut. The immense pressure applied by the hydraulic cylinders allows the shear to efficiently slice through the material, leaving a clean and precise cut. The control valves also allow the operator to adjust the cutting angle and blade clearance, enabling customization according to the specific material and thickness.

Applications of Hydraulic Shears

Hydraulic shears find applications across various industries due to their versatility and ability to handle different materials. Some common applications include:

1. Metal Fabrication: Hydraulic shears are extensively used in metal fabrication shops to cut sheet metal and plate materials. They can handle materials like steel, aluminum, and stainless steel with ease, making them essential tools for creating components used in construction, automotive, aerospace, and other industries.

2. Shipbuilding: In shipyards, hydraulic shears are employed to cut and shape metal plates for ship hulls, decks, and other structural components. Their ability to produce precise cuts is crucial to maintaining the structural integrity of the vessels.

3. Scrap Processing: Hydraulic shears play a vital role in recycling and scrap processing facilities. They are used to cut and process large metal objects like automobiles, appliances, and machinery into manageable pieces for recycling.

4. Demolition:In the demolition industry, hydraulic shears are mounted on excavators and used to cut through reinforced concrete, steel beams, and other materials during the demolition process.

5.Manufacturing: Hydraulic shears are integral to the manufacturing of various products, including metal cabinets, enclosures, and appliances, where precision cuts are essential for ensuring proper fit and functionality.

Advantages of Hydraulic Shears

1.Precision:Hydraulic shears offer exceptional cutting precision, resulting in clean and accurate cuts even in complex shapes and patterns.

2. Powerful Cutting Force: The hydraulic system provides a high cutting force, enabling the shear to easily handle thick and tough materials.

3. Versatility:Hydraulic shears can cut a wide range of materials, from thin sheets to heavy plates, making them suitable for diverse applications.

4. Efficiency: These shears are efficient and time-saving, allowing operators to complete cutting tasks quickly and with minimal effort.

5.Minimal Deformation: The precise cutting action of hydraulic shears reduces material deformation and waste, resulting in higher material utilization.

Post time: Sep-21-2023