The quick hitch coupler of the excavator, also known as the quick-change joint, is installed at the front end of the excavator’s working device. It can realize various excavator attachments such as buckets, breakers, rippers, hydraulics without manually disassembling the pins. The replacement of shears, wood grabs, stone grabs, etc., enables the excavator to expand various operations such as crushing, shearing, cleaning, compaction, milling, pushing, pinching, grabbing, scraping, loosening, hoisting, etc. The attachment replacement process is easy to operate, safe and reliable, saves time, and greatly improves the working efficiency of the excavator.

一.Classification of quick hitch couplers for Excavators

Divided by product structure and functional level, quick hitch couplers can be divided into two categories. One has a simple structure and only has the function of quick-change connection, which is called ordinary quick-change; the other type not only has quick-connect function, but also adds attributes. With freedom, it is called universal quick connection. Only the ordinary quick hitch coupler is introduced here. The ordinary quick change is divided into two types: mechanical and hydraulic according to the driving mode.

二. Features of excavator quick hitch coupler:

1. Use high-strength materials; suitable for various models of 3-80 tons;

2. Use the safety device of hydraulic control check valve to ensure safety;

3. The configuration parts of the excavator do not need to be modified, and can be replaced without disassembling the pin, so the installation is quick and the work efficiency can be greatly improved.

4. There is no need to manually smash the bucket pin between the breaker and the bucket, and the switch can be exchanged between the bucket and the breaker by gently moving the switch for ten seconds, which is time-saving, labor-saving, simple and convenient.

5. It is mainly used in the workplace where the front-end working device of the excavator needs to be frequently replaced. When using a device for a long time, try not to install it.

三.the advantages of choosing HMB quick hitch coupler

1. Welding technology: 12 years of experience, not easy to crack.

2. Grease nipple: make the pin not easy to wear

3. Double lock system: front paw lock and rear safety lock make operation safer. Even if the cylinder suddenly stops working, it can hold the pin tightly.

4. Imported oil cylinder is not easy to damage

5. There is no need for safety pins, and the excavator operator can operate alone in the cab.

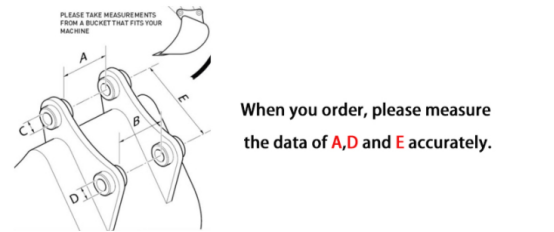

6.Wide application range: Compared with the fixed C to C distance (A) of the conventional quick hook, the multi-speed hook is more flexible. Applicable to all accessories whose distance (A) from C to C is within its range.

Post time: Jun-11-2021