一、Definition of hydraulic breaker

Hydraulic breaker, also known as hydraulic hammer, is a kind of hydraulic mechanical equipment, usually used in mining, crushing, metallurgy, road construction, old city reconstruction, etc. Due to the powerful breaking energy and low noise, the hydraulic breaker has become the first choice for industry construction.

Top hydraulic breaker

Side hydraulic breaker

box hydraulic breaker

Top type rock breaker :In demolition and mine risk management projects, the top type hydraulic hammer operation is more flexible. due to the relatively high installation point of the tower breaker and the excavator, the working range of the tower breaker is relatively larger for the horizontal and grooved working surface.

Side Type Hydraulic Rock Breaker:It adopts the best design scheme, is manufactured with the fewest parts, has few failures and is easy to maintain, and is known for being light and powerful. The triangular hydraulic breaker is more capable of satisfying the needs of users.

Box Silenced Hydraulic Rock Breaker:Quiet model, beautiful appearance, adopts the latest closed shell to protect the host design and vibration reduction and noise reduction technology to meet the various needs of users.

三、Reasons for the continuous innovation of hydraulic breakers

In recent years, with the advancement of urbanization and urban infrastructure construction, a large number of demolition operations are required, which will form a continuous demand for hydraulic breakers;

In recent years, with the advancement of urbanization and urban infrastructure construction, a large number of demolition operations are required, which will form a continuous demand for hydraulic breakers;

In addition, with the country's increasing attention to environmental protection, the continuous improvement of safety production requirements and the gradual rise of labor costs, the utilization rate of hydraulic breakers will increase rapidly, which will also promote continuous innovation of hydraulic breakers. Such as low noise silent type breaker, super-large breaker, special breaker, etc., its application fields are constantly expanding.

In addition, with the country's increasing attention to environmental protection, the continuous improvement of safety production requirements and the gradual rise of labor costs, the utilization rate of hydraulic breakers will increase rapidly, which will also promote continuous innovation of hydraulic breakers. Such as low noise silent type breaker, super-large breaker, special breaker, etc., its application fields are constantly expanding.

Universal applicability of hydraulic drive system, general requirements for improving machine utilization

Universal applicability of hydraulic drive system, general requirements for improving machine utilization

Yantai Jiwei aims to meet the high standards of the current market. The hydraulic equipment's requirements for high durability and low maintenance costs are integrated into the overall design of the hydraulic breaker.

四、Application range of hydraulic breaker

>Mine mining: mountain opening, mining, secondary crushing.

>Metallurgy: ladle, slag cleaning, furnace dismantling, and equipment foundation dismantling.

>Railway: tunnel excavation, road and bridge demolition, roadbed consolidation.

>Highway: highway repair, cement pavement broken, foundation excavation.

>Municipal gardens: concrete crushing, water, electricity and gas engineering construction, old city reconstruction.

>Construction: old buildings are demolished, reinforced concrete is broken.

>Ship: Removal of clams and rust from the hull.

>Others: breaking ice and breaking frozen soil.

五、What are the advantages of a Hydraulic rock Breaker?

1. High efficiency, saving manpower and material resources

2. Energy saving, lower operating costs, lower investment costs

3. High precision

4. Lower noise

5. Low vibration

6. Constant forging quality

7. Wide range of applications

8 Easy to maintain and operate, safer

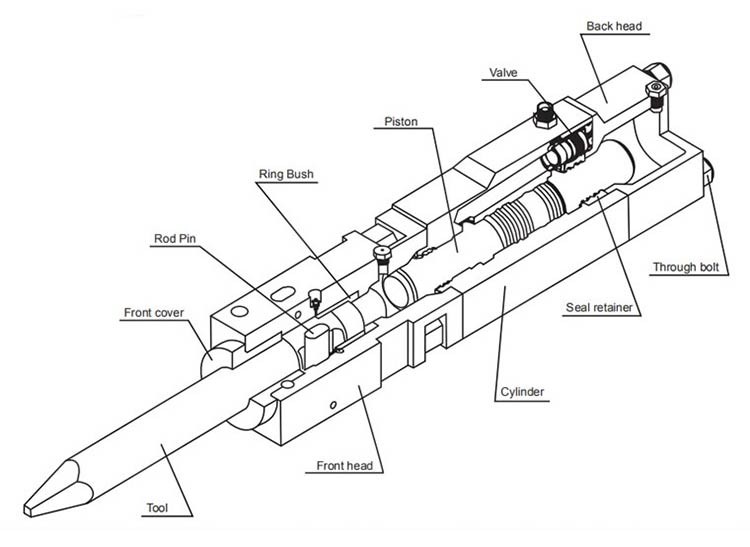

The hydraulic system includes a hydraulic accumulator. The principle is to use the breaker to store the remaining energy and the energy of the piston recoil during the previous strike, and release the energy at the same time during the second strike to increase the striking ability. Usually It is to install an accumulator when the blow energy itself cannot reach to increase the blow power of the crusher. Generally, there are no accumulators for small and medium-sized ones, and accumulators for medium and large ones.

六、How Does a Hydraulic Breaker Work?

The hydraulic inlet and the upper accumulator push the cylinder rod upward to compress the nitrogen chamber. After pushing to the highest point, the reversing valve switches the direction. The hydraulic inlet and nitrogen compression push the cylinder rod down quickly to knock the drill rod down to complete the crushing work.

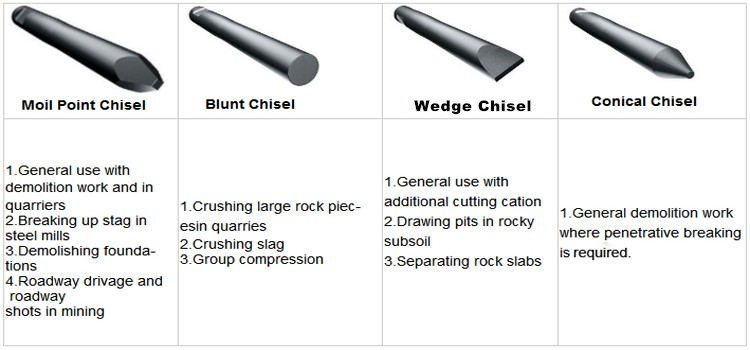

Replaceable Tools

Demolition hammers can be operated with different accessories. The most common are all kinds of chisels.

七、How to choose a hydraulic breaker for an excavator?

1. First of all, we must consider the weight of the excavator. Only when the weight of the excavator and the hydraulic breaker are matched can the capabilities of the two be fully utilized. If the hydraulic breaker is too heavy, it will cause the excavator to roll over, and if the hydraulic breaker is too small, the excavator cannot be realized. The economic efficiency will also accelerate the damage of the breaker.

2. The second point to consider is whether the flow rate of the breaker is consistent with the output flow of the excavator. If it is greater than the flow rate of the hydraulic breaker, the life of the component will be damaged. If it is less, the piston may not start.

Of course, in order to determine the most suitable hydraulic breaker, experts consider a variety of factors, such as the materials to be removed and the surrounding environment.

Post time: May-17-2021