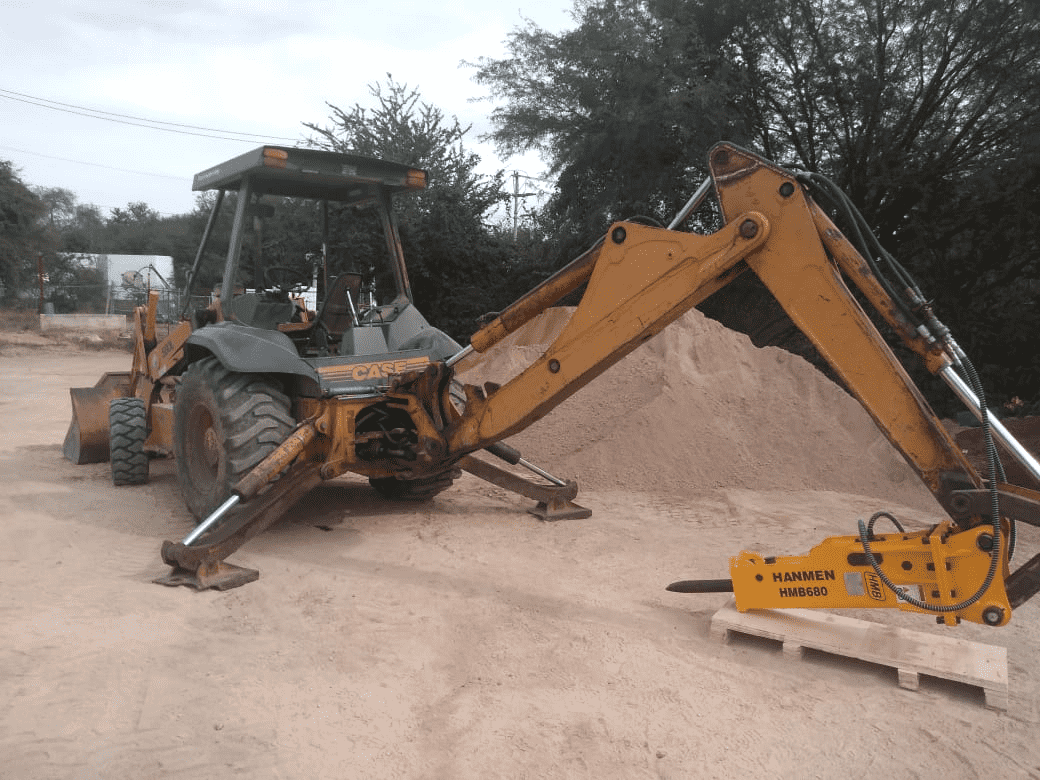

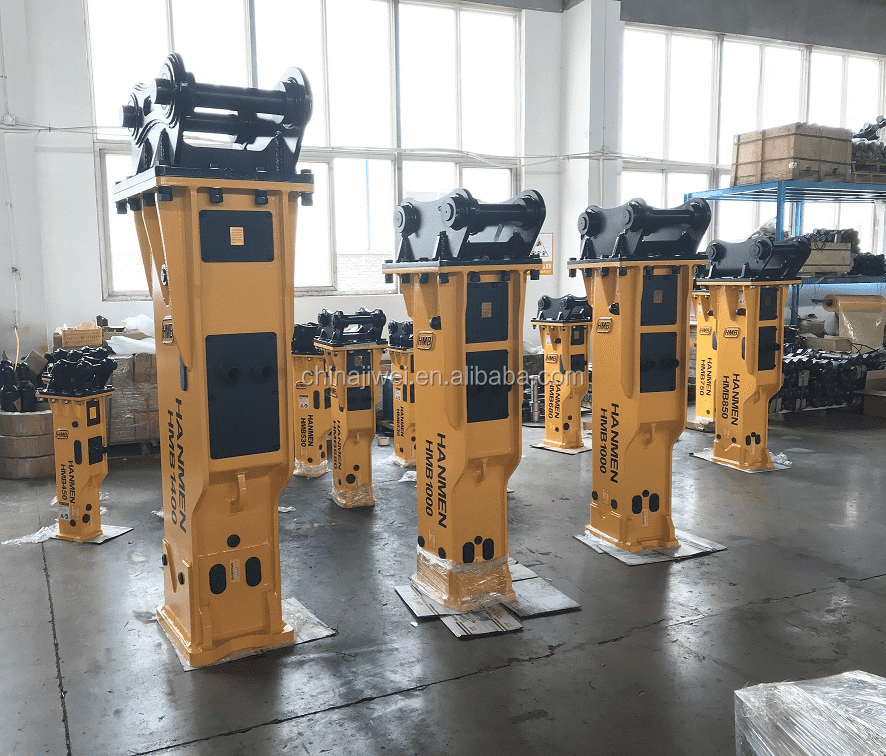

Do you know the working principle after configuration?

After the hydraulic breaker is installed on the excavator, whether the hydraulic breaker works will not affect the normal operation of other devices of the excavator. The pressure oil of the hydraulic breaker is provided by the main pump of the excavator. The working pressure is regulated and controlled by the overflow valve. In order to adjust the parameters of the hydraulic system, the inlet and outlet of the hydraulic breaker must be equipped with a high-pressure stop valve.

Common faults and principles

Common faults: the working valve of the hydraulic breaker is worn, the pipeline bursts, and the hydraulic oil is locally overheated.

The reason is that the skills are not well configured, and the on-site governance is not good.

reason: The working pressure of the breaker is generally 20MPa and the flow rate is about 170L/min, while the working pressure of the excavator system is generally 30MPa and the flow rate of the single main pump is 250L/min. Therefore, the overflow valve bears the burden of diversion. The flow valve was damaged and was not discovered in time. Therefore, the hydraulic breaker will work under ultra-high pressure, resulting in the following consequences:

1: The pipeline bursts, the hydraulic oil is locally overheated;

2:The main directional valve is severely worn, and the hydraulic circuit of other spools of the excavator’s main working valve group is contaminated;

3:The oil return of the hydraulic breaker is generally directly passed through the cooler. The oil filter returns to the oil tank, and it circulates several times in this way, causing the oil temperature of the oil circuit to be high, which seriously reduces the service life of the hydraulic components.

Resolution measures

The most effective measure to prevent the above failures is to improve the hydraulic circuit.

1. Install an overload valve at the main reversing valve. The set pressure is better to be 2~3MPa larger than the relief valve, so as to reduce the impact of the system and ensure that the system pressure will not be too high when the relief valve is damaged. .

2.when the flow of the main pump exceeds 2 times the maximum flow of the breaker, a diverter valve is installed in front of the main reversing valve to reduce the load of the overflow valve and prevent local overheating.

3. Connect the oil return line of the working oil circuit to the front of the cooler to ensure that the working oil return is cooled.

Post time: Apr-16-2021