It is more and more common to install hydraulic breakers on excavators. Improper use will damage the hydraulic system and the life of the excavators. so proper use can effectively extend the service life of the hydraulic system and the service life of the excavator

content:

1.How to extend the life of a hydraulic breaker

●Use high-quality breakers (preferably hydraulic breakers with accumulators

●Appropriate engine speed

●Correct butter posture and correct replenishment frequency

●Hydraulic oil quantity and pollution status

●Replace the oil seal in time

●Keep the pipeline clean

●The hydraulic system should be preheated before the breaker is used

●Uninstall when saving

2.contact HMB Hydraulic Breaker Manufacturer

1. Use high-quality breakers (preferably hydraulic breakers with accumulators)

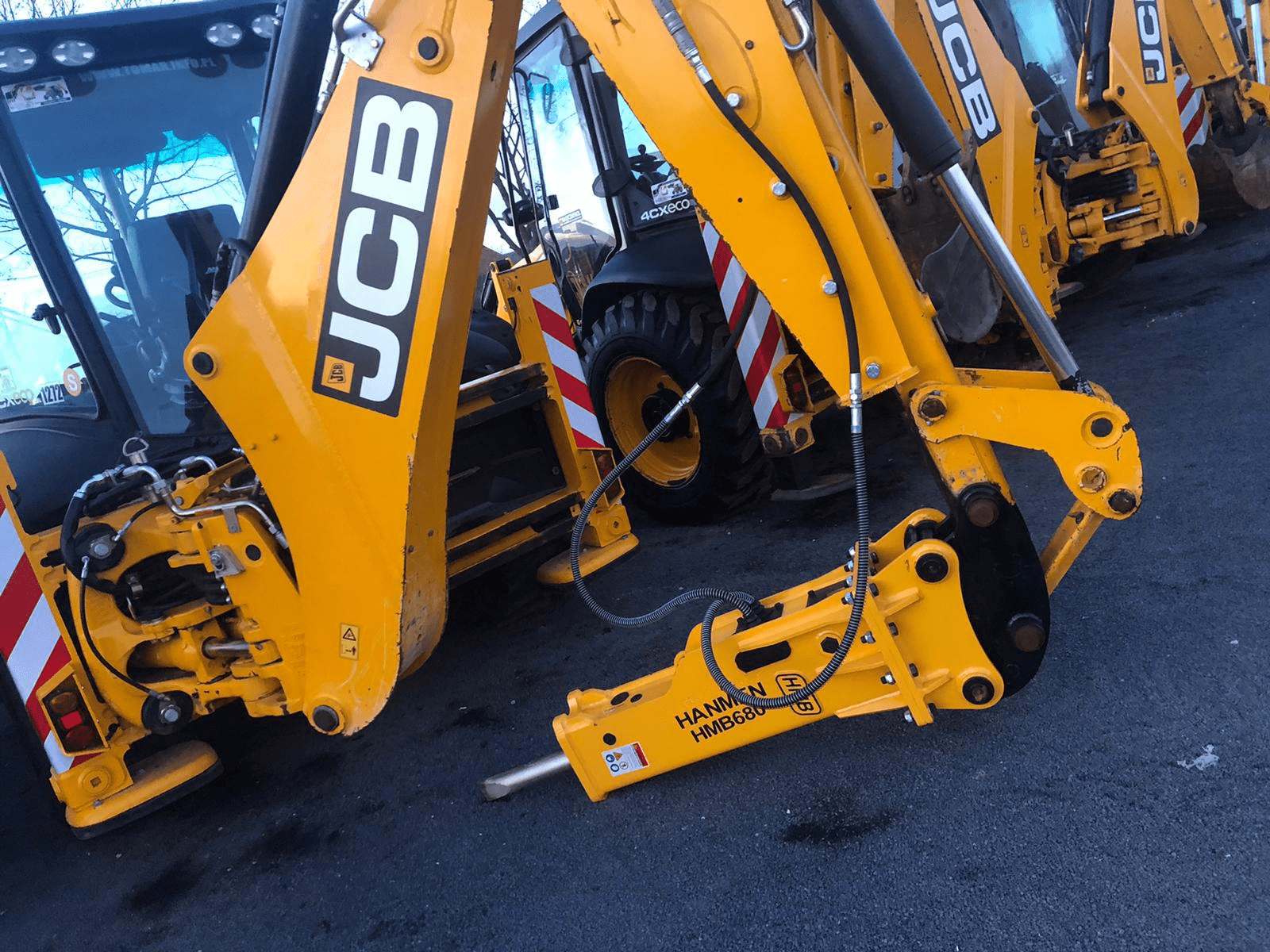

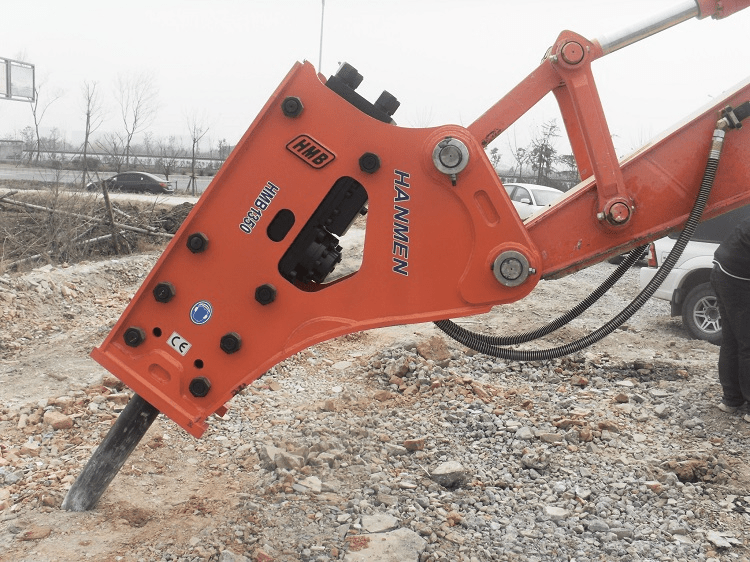

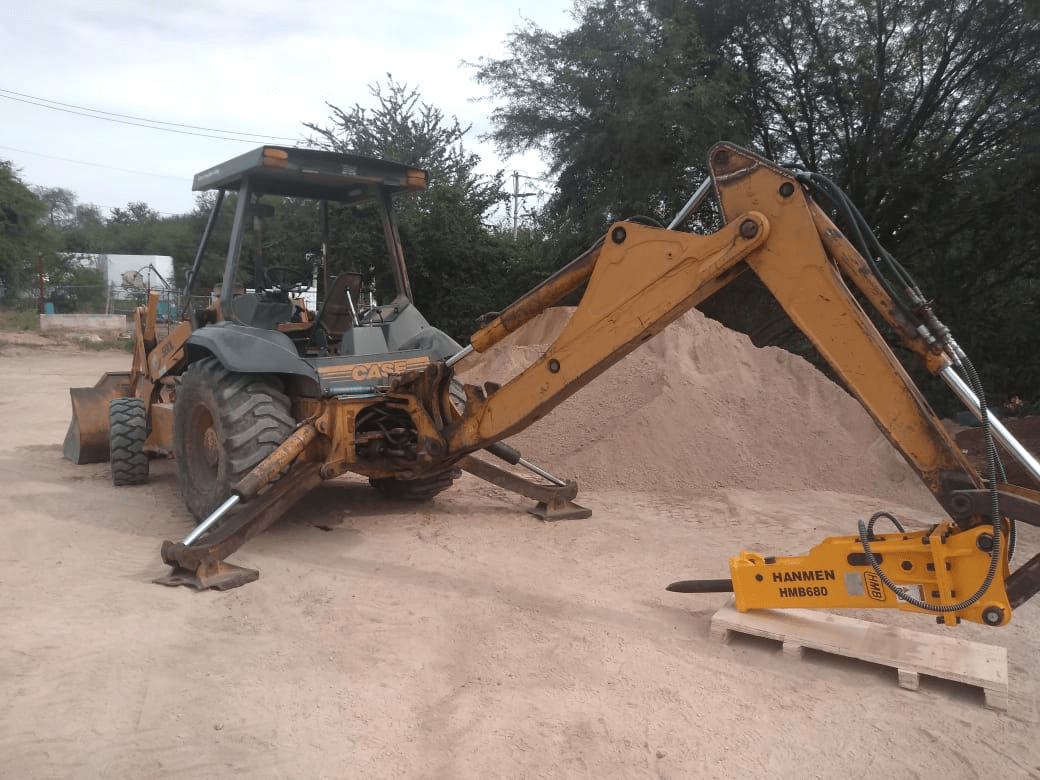

Inferior quality breakers are prone to various problems in the stages of material, production, testing, etc., resulting in a high failure rate during use, high maintenance costs, and more likely to cause damage to the excavator. Therefore, it is necessary to use high-quality hydraulic breakers. Recommend HMB hydraulic breaker, first-class quality, first-class service, worry-free after-sales service, you will definitely get twice the result with half the effort.

2.Appropriate engine speed

Since hydraulic breakers have low requirements for working pressure and flow (such as a 20-ton excavator, working pressure 160-180KG, flow 140-180L/MIN), working conditions can be achieved under medium throttle conditions; if you use high throttle, not only If the blow is not increased, it will cause the hydraulic oil to heat up abnormally, which will cause greater damage to the hydraulic system.

3. Correct butter posture and correct replenishment frequency

The butter must be kept in the air when the steel is pressed straight, otherwise the butter will enter the striking chamber. As the hammer works, abnormal high-pressure oil will appear in the striking chamber, which will damage the life of the hydraulic system. Add butter The frequency is to add butter every 2 hours.

4. Hydraulic oil quantity and pollution status

When the amount of hydraulic oil is small, it will cause cavitation, which will cause hydraulic pump failure, breaker piston cylinder strain and other problems. Therefore, it is best to check the oil level before each use of the excavator to see if the amount of hydraulic oil is sufficient.

Hydraulic oil contamination is also one of the main causes of hydraulic pump failure, so the contamination status of hydraulic oil should be confirmed in time. (Change the hydraulic oil in 600 hours, and replace the core in 100 hours).

5. Replace the oil seal in time

The oil seal is a vulnerable part. It is recommended that the hydraulic breaker be replaced every 600-800 hours of work; when the oil seal leaks, the oil seal must be stopped immediately and the oil seal must be replaced. Otherwise, side dust will easily enter the hydraulic system and damage the hydraulic system.

6. Keep the pipeline clean

When installing the hydraulic breaker pipeline, it must be thoroughly cleaned, and the oil inlet and return lines must be cyclically connected; when replacing the bucket, the breaker pipeline must be blocked to keep the pipeline clean; otherwise, sand and other debris will be easy to enter the hydraulic system Damage to the hydraulic pump.

7. The hydraulic system should be preheated before the breaker is used

When the hydraulic breaker is parked, the hydraulic oil from the upper part will flow to the lower part. It is recommended to operate with a small throttle at the beginning of use every day. After the oil film of the piston cylinder of the breaker is formed, use the medium throttle to operate, which can protect Excavator hydraulic system.

8. Uninstall when saving

When storing the hydraulic breaker for a long period of time, the steel drill should be removed first, and the nitrogen in the upper cylinder should be released to prevent the exposed part of the piston from rusting or fraying, which would damage the hydraulic system.

Post time: Aug-19-2021